Comprehensive Guide to the Design, Manufacture, and Installation of Bespoke Industrial Cooling Systems for Efficient Process Cooling Solutions

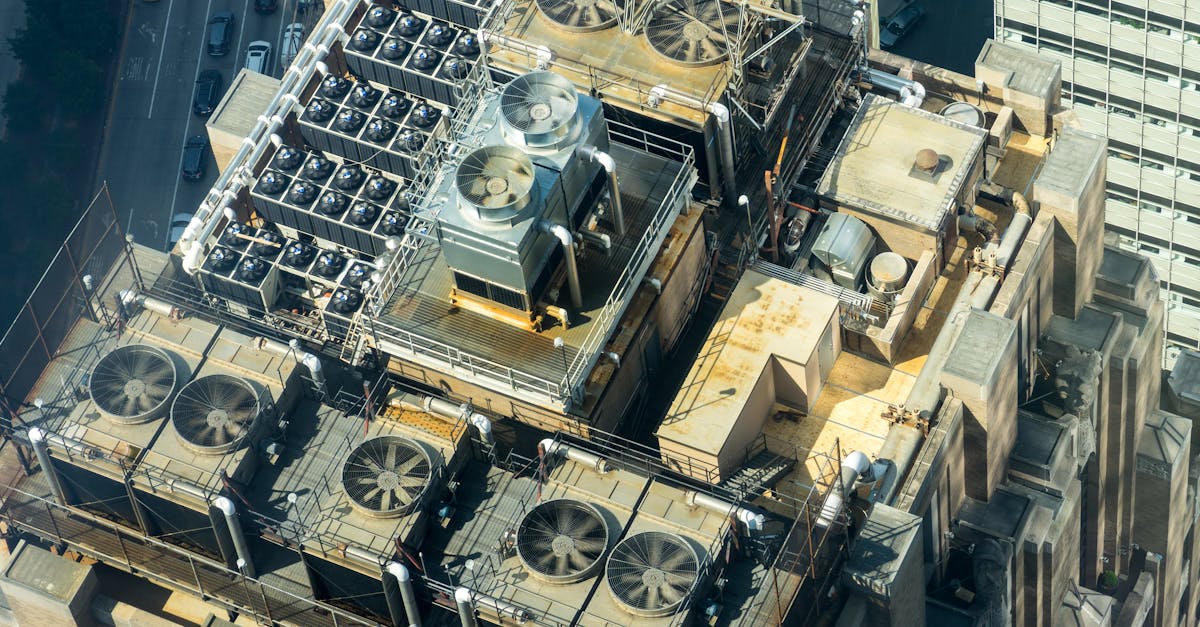

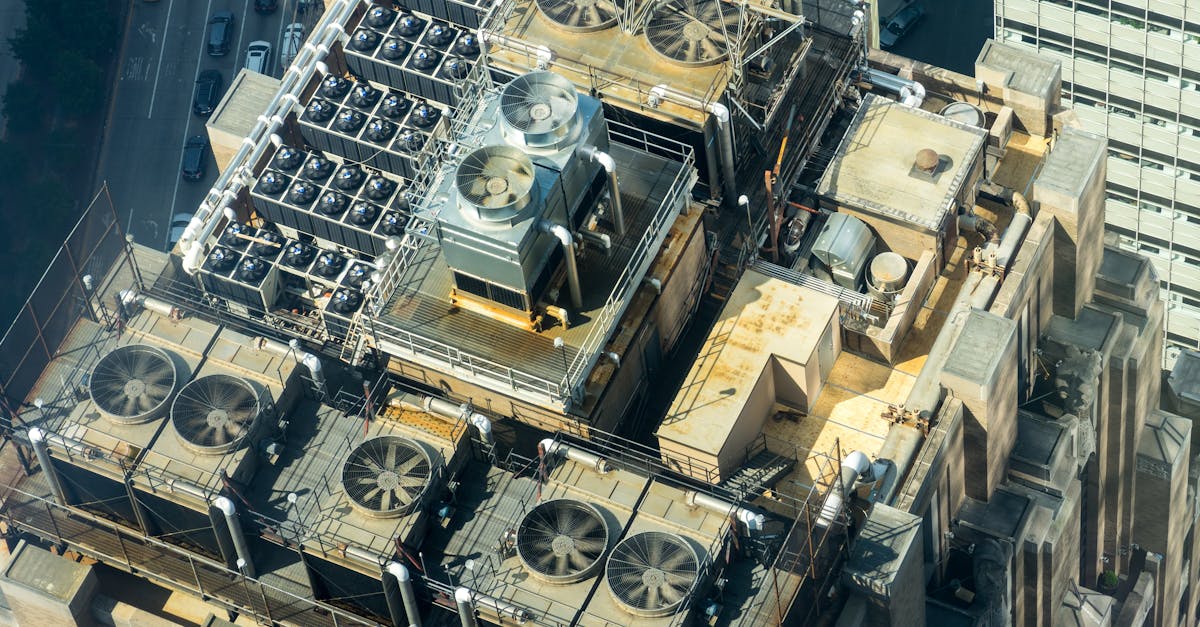

Industrial cooling systems are essential for managing temperatures in various industrial applications. They can efficiently regulate heat through mechanisms such as water-cooling and evaporative cooling, ensuring optimal operational conditions. The cooling capacity of these systems directly impacts the performance of machinery and processes, making them integral to industries like manufacturing and power generation. Techniques like once-through cooling and free-cooling are employed to enhance efficiency, while cooling towers play a pivotal role in dissipating heat. Effective management of cooling water is crucial, as it supports the overall functionality of water-cooled systems while addressing environmental concerns.

Definition of Industrial Cooling Systems

Industrial cooling systems from Summit Process Cooling are essential components in various manufacturing processes that help manage heat and maintain optimal temperature levels. These systems facilitate temperature control by using mechanisms such as heat exchangers, air conditioning units, and heat pumps. From charge air coolers to advanced air coolers, each element plays a critical role in removing excess heat generated by equipment and processes, ensuring that operational efficiency is achieved while preventing overheating.

The functionality of industrial cooling systems extends to both cooling and heating applications. Heaters can be integrated with these systems for precise temperature management, catering to diverse needs within industrial settings. Effective heat recovery systems contribute significantly to energy efficiency, enabling industries to optimise their cooling operations while minimising energy waste. The interplay between cooling systems and temperature regulation is vital for maintaining safe and productive working environments.

Importance of Industrial Cooling

Industrial cooling systems play a pivotal role in maintaining optimal temperatures across various sectors. Factories and manufacturing plants rely heavily on effective climate control to ensure machinery operates within its critical temperature limits. This is vital for preventing overheating, which could lead to equipment failure or reduced productivity. Portable air conditioning units and evaporative coolers offer flexible solutions for spaces requiring additional cooling support, particularly in hot weather conditions.

The need for proper cooling extends beyond machinery; it is essential for processes such as cold storage and the operation of boilers. Effective air-conditioning helps preserve product quality and safety in food processing and pharmaceuticals. Condensers also play an integral role in industrial cooling systems, facilitating the removal of excess heat. Overall, the importance of industrial cooling cannot be overstated, as it directly influences operational efficiency and product integrity.

- Ensures machinery longevity by preventing overheating

- Supports consistent production rates and reduces downtime

- Enhances product quality and safety in sensitive industries

- Allows for flexible and scalable cooling solutions

- Improves energy efficiency and reduces operational costs

- Protects the integrity of critical processes such as refrigeration

- Contributes to overall workplace safety and comfort

Types of Cooling Systems

Industrial cooling systems are essential for maintaining optimal operating conditions in various manufacturing environments. Two primary categories are air-cooled and water-cooled systems. Air-cooled systems use compressors and air conditioners to condense refrigerants, effectively regulating temperatures in machinery and enhancing air quality. These systems are often preferred in areas with limited water access, as they rely solely on air to dissipate heat. Conversely, water-cooled systems utilise chillers that circulate water to absorb heat from equipment, providing more efficient cooling, especially in large-scale operations that demand consistent power supply and humidity control. Each type plays a critical role in ensuring efficient performance and longevity of industrial cooling systems, tailored to specific operational needs.

- Air-cooled systems are typically easier to install and maintain.

- Water-cooled systems are generally more efficient in heat exchange.

- Air-cooled systems may have lower initial costs.

- Water-cooled systems can support larger cooling loads.

- Air-cooled systems are suitable for smaller operations or those in arid regions.

- Water-cooled systems can lead to higher energy savings in the long run.

- Regular maintenance is crucial for both system types to ensure optimal performance.

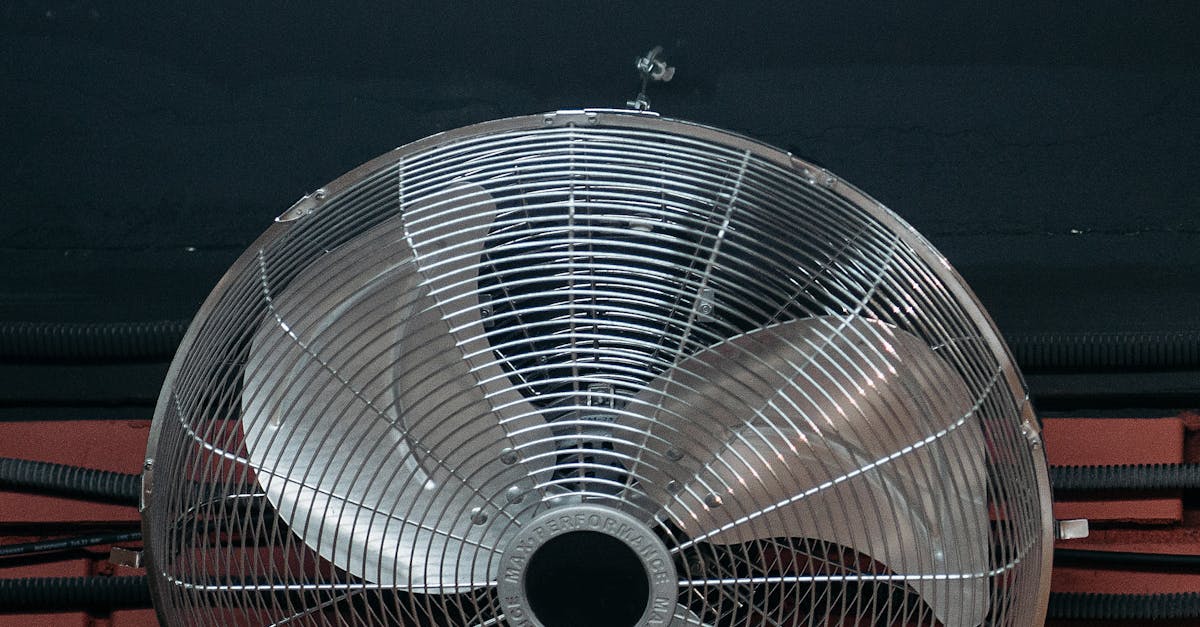

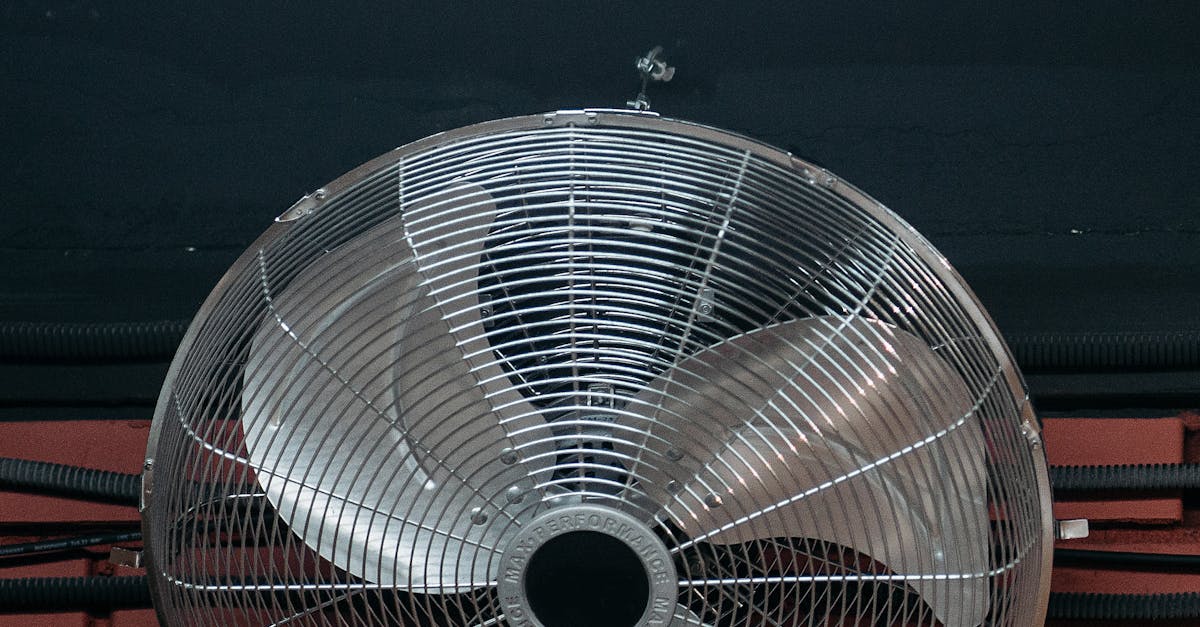

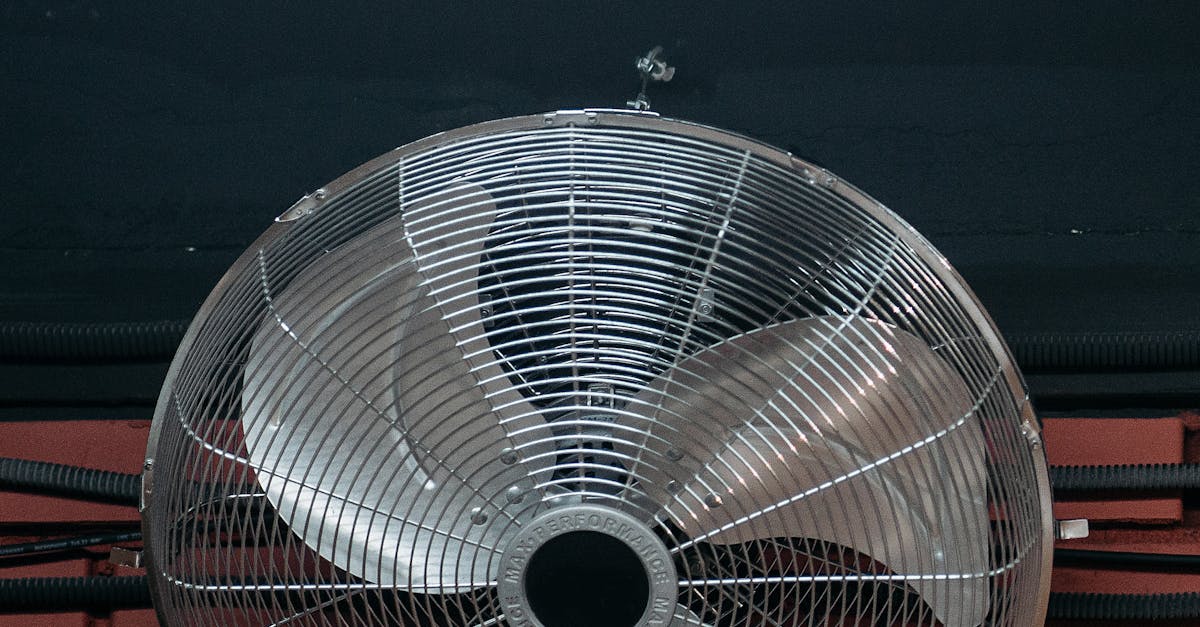

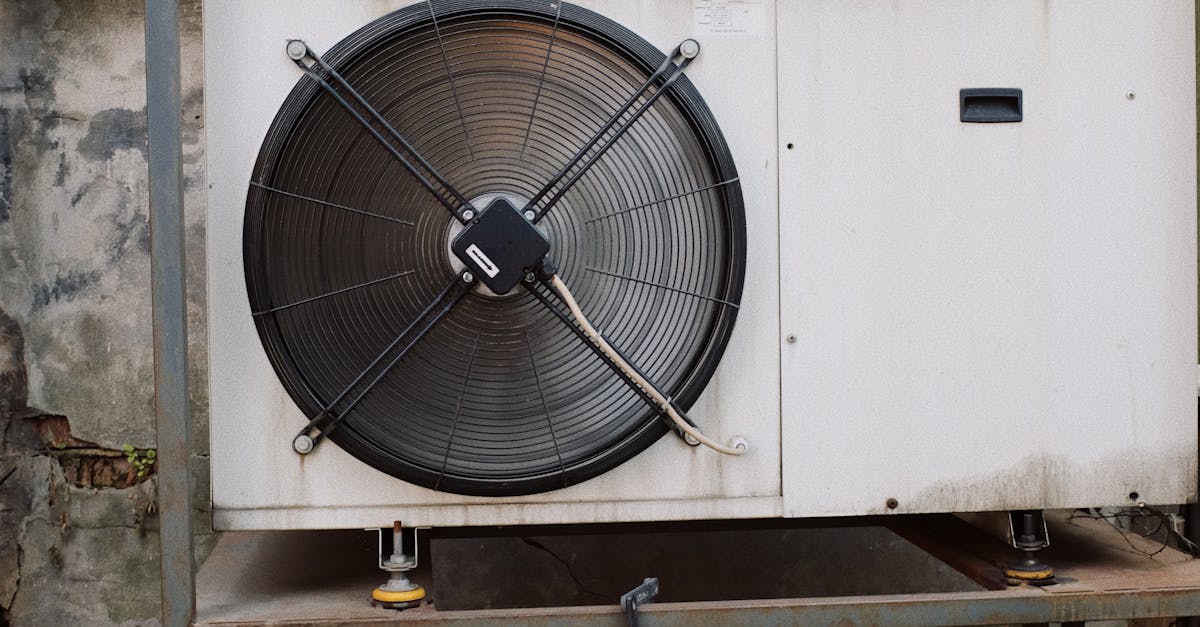

Air-Cooled Systems

Air-cooled systems play a crucial role in various industrial cooling projects due to their ability to effectively manage the heat generated by machinery and processes. By utilising ambient air for cooling, these systems reduce dependency on water resources and can operate efficiently in areas where water availability is limited. The design of these systems focuses on maximising airflow and maintaining optimal ventilation, which contributes significantly to their overall energy efficiency. Lower electricity consumption is a key benefit of air-cooled systems, making them an appealing choice for industries aiming to reduce power consumption and operational costs.

The integration of advanced industrial cooling equipment enhances the performance of air-cooled systems, allowing for improved heat exchange processes. These systems can be tailored to specific requirements, ensuring adequate cooling for various industrial applications. Understanding the dynamics of airflow and the surrounding environment is essential for optimising the efficiency of these cooling systems. Proper selection and installation of air-cooled industrial cooling systems can lead to significant energy savings while maintaining the necessary cooling capacities for critical operations.

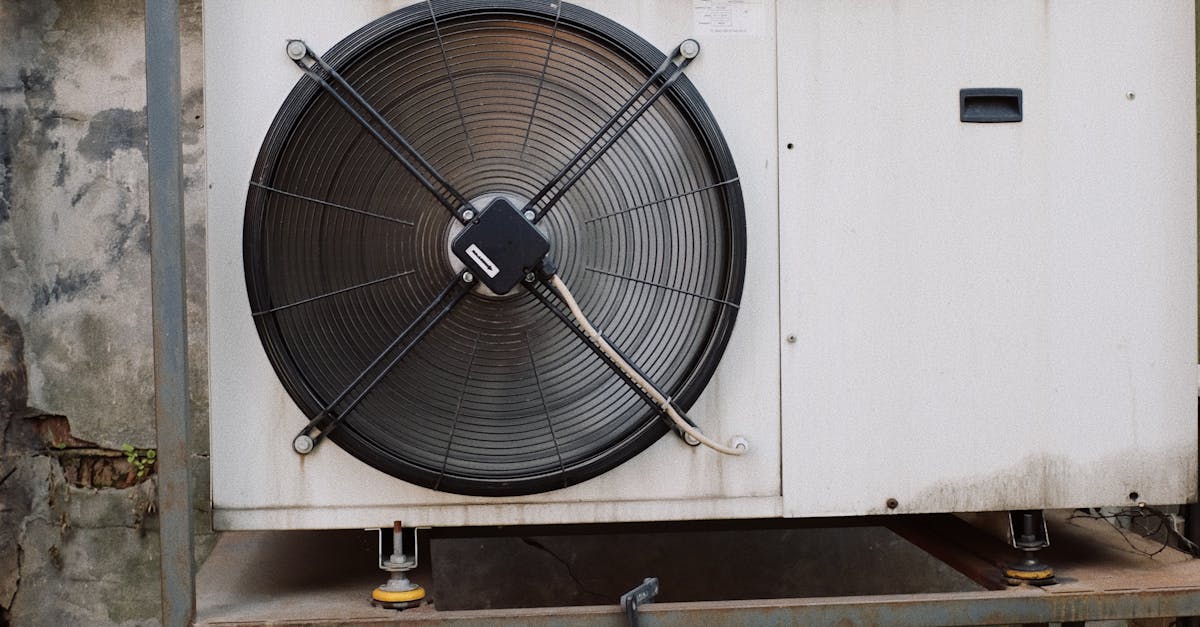

Water-Cooled Systems

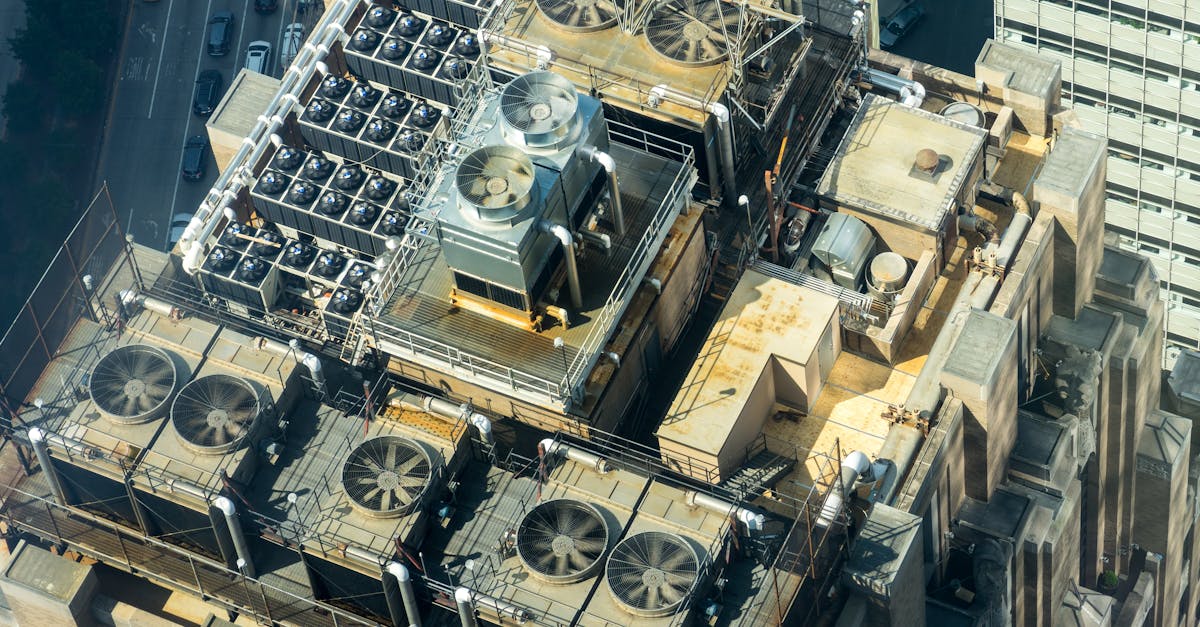

Water-cooled systems play a crucial role in industrial cooling systems by efficiently managing high-capacity cooling requirements. These systems utilise water as the primary cooling medium, making them ideal for large-scale operations where cooling load can be substantial. The water-cooling industry has developed innovative cooling technology that ensures optimal performance and reliability, particularly in applications requiring intensive process cooling. Businesses can benefit from reduced industrial cooling costs due to the energy efficiency of water-cooled systems, which often outperform air-cooled alternatives in demanding environments.

The implementation of water-cooled solutions is prevalent in various commercial cooling solutions across sectors such as manufacturing and power generation. These cooling systems are designed to handle significant thermal loads while maintaining operational safety and efficiency. Properly designed and maintained water-cooling systems can provide long-term durability and performance. A well-optimised cooling solution also plays a vital role in extending the lifespan of equipment and minimising downtime, thereby enhancing overall productivity in industrial settings.

Applications of Industrial Cooling

Industrial cooling systems play a crucial role in meeting various cooling needs across different sectors. Process cooling, for example, requires reliable cooling to maintain optimal production conditions, ensuring efficiency and preventing overheating. High-performance cooling solutions, such as air-cooled systems, provide exceptional cooling capacity while delivering precise cooling temperature control. In settings where instant cooling is essential, these systems demonstrate their powerful cooling capabilities. Industrial power cooling also benefits from advanced cooling technologies, which help regulate temperature in energy-intensive processes. Overall, efficient cooling solutions are vital for operational success, safeguarding equipment and enhancing productivity.

Process Cooling

Effective temperature control is critical in various industrial operations. Industrial cooling systems, particularly those using water-cooled systems, provide consistent cooling necessary for maintaining optimal process conditions. Centralised cooling solutions help in managing multiple cooling circuits simultaneously, ensuring that all equipment remains within operational temperature limits. High-power cooling is essential in environments that require event cooling, where sudden temperature spikes need immediate attention.

The design of industrial chillers specifically targets the removal of heat generated by machinery and processes. This approach ensures cost-effective cooling while maintaining superb cooling performance without excessive noise. Quiet cooling features are often integral to modern industrial cooling systems, allowing operations to continue without disruption. Such considerations are vital for industries that rely on efficient, reliable temperature regulation in their processes.

Industrial Power Cooling

Power generation facilities rely heavily on effective temperature control equipment to manage heat produced during industrial processes. Industrial cooling systems, such as industrial chillers and industrial air-conditioners, ensure optimal operating conditions by removing excess heat, which enhances the efficiency and longevity of equipment. Seasonal energy performance ratio (SEPR) plays a crucial role in process cooling by determining the energy efficiency of these systems, impacting both operational costs and environmental sustainability.

Rental cooling solutions have become increasingly popular for industrial power applications, providing flexibility during peak loads or system failures. These temporary systems, including dual spot cooling setups, offer a reliable way to maintain temperature control without significant downtime. With robust industrial refrigeration options, facilities can adapt to varying demands, ensuring that industrial air remains at appropriate temperatures for seamless operation across various industrial processes.

Industrial Cooling Products

Advanced technology plays a pivotal role in the realm of industrial cooling systems, particularly in addressing the diverse needs of sectors such as mining. Numerous mine cooling applications necessitate efficient temperature control solutions to combat real-world process temperature challenges. Options like industrial chiller hire provide crucial support for critical temperature applications where temporary heating may be required. Portable air con/heat units and specialised air-conditioning systems contribute to complete temperature control, ensuring optimal conditions are maintained even under pressure. These innovative industrial cooling systems are essential for achieving performance efficiency across various industrial environments.

Advanced Cooling Products

Advanced cooling technology has transformed industrial cooling systems, enabling facilities to optimise efficiency and reduce operational costs. Free coolers and low GWP chillers are particularly noteworthy, offering solutions that require no capital investment while providing significant benefits such as cost-effective cooling. For instance, a plastic moulding company benefits from a free cooling and flex hire scheme that tackles energy use and maintenance downtime effectively. These advancements also include process chiller options designed to cater to diverse industrial needs, ensuring reliable performance even in demanding environments.

Overcoming logistical challenges is essential, especially in crucial applications like hospitals. An example includes upgrading critical cooling systems for a hospital in Scotland, ensuring uninterrupted operation. Cutting-edge options such as vertical generator coolers and comprehensive chiller maintenance contribute to a stable environment where con/heat management is paramount. These developments in industrial cooling systems not only enhance functionality but also support sustainability objectives across various sectors.

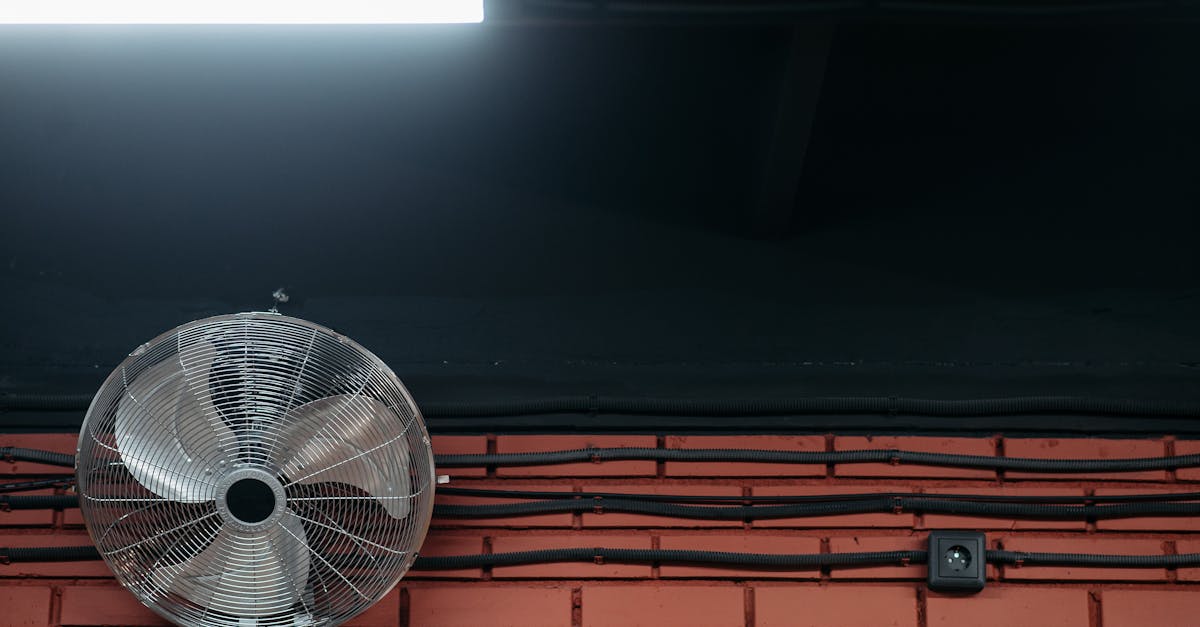

Industrial Air Coolers

Air coolers play a crucial role in industrial cooling systems, especially in environments where maintaining stable temperatures is vital. These units, equipped with windfree technology, help ensure that high temperatures do not compromise operations. A notable example includes contingency cooling for Birmingham hospitals' data centre and comfort cooling for patient wards, where efficient climate control is paramount to safeguarding sensitive equipment and patient wellbeing.

As seen in the case of Baxter’s futureproofing of vinegar production with a new cooling system from ICS Cool Energy, the adaptability of air coolers makes them invaluable. Their design allows for effective cold storage in London while offering the option of portable spot coolers for specific needs. These coolers provide a reliable method for maintaining safe temperature limits, ensuring that processes remain uninterrupted even during peak demand periods.

Cooling Challenges in Industrial Settings

Addressing the challenges in industrial cooling settings is crucial for optimising the performance of industrial cooling systems. Effective management of temperature increases is essential, particularly in environments such as machining centres where maintaining the desired temperature directly influences manufacturing efficiency. High-performance air conditioning solutions can significantly enhance ventilation projects, ensuring a steady airflow while keeping temperatures stable. The need for equipment solutions, including refrigeration-based systems and cold storage hire, has escalated as industries strive to adapt to fluctuating demands. Recent initiatives, such as the establishment of ICS Cool Energy's full-scale depot in Birmingham, demonstrate the industry's commitment to improving service delivery and performance in maintaining heating and hot water supplies in schools and universities. These developments highlight the ongoing need for innovative strategies to manage cooling challenges in various industrial applications.

Environmental Considerations

Industrial cooling systems play a crucial role in mitigating the environmental impact associated with production machinery. Efficiently managing hot water supplies is vital, especially in the steel-making process, where high temperatures are commonplace. As commercial settings strive for greener operations, incorporating eco-friendly technology into these systems not only enhances manufacturing efficiency but also addresses the challenges posed by high humidity.

The rising demand for rapid chiller hire and temporary chiller hire options highlights the necessity for flexible cooling solutions in various industrial applications. Climate control is becoming increasingly important as businesses seek to balance operational needs with sustainability goals. By adopting innovative approaches within industrial cooling systems, manufacturers can reduce their environmental footprint while maintaining optimal performance and reliability.

Efficiency and Performance Issues

Efficiency in industrial cooling systems plays a crucial role in manufacturing processes, particularly during record-breaking heat or hot summer days. The adoption of energy-efficient inverter technology has gained momentum, allowing for energy-saving inverter solutions that significantly reduce power consumption. These systems operate using a compact ceiling design, maximising space and ensuring an optimal indoor environment for employees and equipment alike. With the potential to decrease operational costs, these advancements greatly benefit businesses seeking a competitive edge.

Performance issues often arise due to excess moisture and circuit wet conditions within industrial cooling systems. Such factors can compromise the reliability and efficiency of these systems, leading to increased operational costs and reduced productivity. Ensuring compliance with the energy efficiency class standards becomes essential in mitigating these challenges. Regular assessments and updates to the cooling systems can assist in maintaining optimal performance, ultimately supporting smoother manufacturing operations.

Industrial Cooling Services

Effective installation and maintenance services are crucial for the optimal performance of industrial cooling systems. These systems, designed to maintain low temperatures in various applications, rely on efficient airflow and well-regulated refrigerant gas flow to function effectively. Careful attention to details like airflow distribution and built-in air filtration ensures that the systems operate with low energy consumption and minimal electricity costs. Companies often seek chiller hire as a practical solution for temporary cooling needs, especially during peak seasons. A large water tank can enhance seasonal energy performance, delivering reliable cooling while maintaining efficient airflow, which is essential for industrial processes. Regular maintenance services play a vital role in sustaining performance and extending the lifespan of cooling systems.

Installation Services

Proper installation of industrial cooling systems is essential for optimal performance and efficiency. A well-executed setup ensures that the systems function effectively, reducing power consumption significantly. By utilising advanced inverter systems, industries can keep power consumption low while efficiently cooling critical processes. Furthermore, portable air con units offer flexibility, making it easier for various industries to adapt to seasonal demands while maintaining a steady flow of fresh air.

A qualified installation team will assess site requirements and recommend the most suitable cooling systems tailored to specific operational needs. This can include the strategic placement of pump units to maximise airflow and cooling efficiency across the facility. By ensuring that industrial cooling systems are installed correctly, businesses can enhance their productivity, reduce operational costs, and ultimately create a more comfortable working environment for their employees.

Maintenance and Support

Support for industrial cooling systems is crucial to ensure their efficiency and longevity. High-capacity units must undergo regular inspections and maintenance to prevent costly downtime. Servicing equipment that employs advanced inverter technology enhances performance and energy efficiency. Portable air conditioning systems also benefit from timely upkeep to maintain optimal functionality, especially in dynamic industrial settings.

Experienced technicians are essential for executing installation and support for high-performance air systems. These professionals can address complex processes associated with various industrial cooling systems. Companies like Equipment Ltd offer tailored maintenance packages, ensuring that every piece of equipment operates at peak efficiency. Regular maintenance not only extends the life of the system but also ensures compliance with industry standards.

Industrial cooling systems play a crucial role in maintaining optimal operating conditions across various industries. Their ability to effectively manage heat is vital for enhancing performance and prolonging equipment lifespan. Utilising high-quality materials in the construction of these systems not only ensures durability but also supports improved energy efficiency. As industries expand, the capacity of cooling systems becomes increasingly important to meet higher demands. A well-implemented cooling solution not only safeguards processes but also contributes to sustainable business operations. Emphasising the importance of selecting and maintaining the right industrial cooling systems is essential for achieving these objectives.

- Home

- Top Reads

- Roundup of Best Practices for Performance Monitoring in Cooling

- List of Essential Performance Indicators for Cooling Systems

- Review of Top Monitoring Tools for Industrial Cooling Systems

- Why Monitoring Technologies Matter in Industrial Cooling

- Historical Developments in Cooling System Monitoring

- What to Consider for Real-time Monitoring of Cooling Systems

- Why Regular Performance Evaluations are Crucial for Cooling Systems

- What to Look for in Cooling System Performance Reports

- How to Implement Effective Monitoring for Industrial Cooling Systems

- How to Evaluate Performance Metrics in Cooling Systems

- Roundup of Best Practices for Upgrading Industrial Cooling Systems

- Review of the Latest Technologies in Cooling Equipment Upgrade

- 8 Signs It’s Time to Upgrade Your Cooling Equipment

- Historical Innovations in Industrial Cooling Equipment Upgrades

- Why Regular Upgrades Are Essential for Cooling Equipment

- What Upgrading Cooling Equipment Means for Your Operation

- Why Upgrading Your Cooling Systems Can Save Costs

- What to Consider When Upgrading Industrial Cooling Equipment

- How to Assess the Need for Upgrading Your Cooling Systems

- How to Upgrade Your Industrial Cooling Equipment for Maximum Efficiency

- Top Strategies for Addressing Cooling System Operational Failures

- A Comprehensive Review of Troubleshooting Cooling System Defects

- 7 Common Problems in Industrial Cooling Systems and Their Solutions

- Why Regular Diagnostics Are Essential for Cooling Systems

- Historical Changes in Maintenance Techniques for Cooling Systems

- Why Overheating Occurs in Industrial Cooling Systems

- What to Check for Blocked Airflow in Cooling Units

- What to Do When Your Cooler Is Not Maintaining Temperature

- How to Resolve Faulty Thermostat Issues

- 7 Tips for Improving Energy Efficiency in Cooling Systems

- How to Identify Common Failures in Industrial Cooling Systems

- Review of Top Energy-efficient Cooling Solutions for Industries

- Roundup of Effective Energy Efficiency Strategies for Cooling

- Historical Advances in Energy Efficiency for Cooling Systems

- What to Consider for Energy-efficient Cooling System Design

- Why Upgrading to Modern Cooling Technologies Matters

- Why Energy Efficiency is Crucial for Industrial Cooling Systems

- What are the Best Practices for Enhancing Cooling System Efficiency

- How to Conduct an Energy Audit for Cooling Equipment

- How to Maximise Energy Efficiency in Industrial Cooling Systems

- Roundup of Common Maintenance Mistakes to Avoid in Cooling Systems

- Review of Best Practices for Industrial Cooling System Maintenance

- 7 Essential Tools for Cooling System Maintenance

- Historical Evolution of Maintenance Practices in Cooling Systems

- Why Neglecting Cooling System Maintenance Can Lead to Equipment Failure

- Why Regular Maintenance is Essential for Cooling System Efficiency

- What are the Benefits of Regular Maintenance for Industrial Cooling Systems

- What to Include in Your Cooling System Maintenance Checklist

- How to Identify Common Signs of Cooling System Deterioration

- How to Implement a Regular Maintenance Schedule for Cooling Systems

- Review of Technologies for Ensuring Product Quality in Cooling Systems

- Roundup of Best Practices for Maintaining Product Quality with Cooling

- Historical Advances in Cooling Systems and Their Impact on Product Quality

- Top 10 Benefits of Enhanced Cooling for Product Quality

- Why Enhanced Cooling Systems Lead to Better Product Quality

- Why Consistency is Key in Industrial Cooling for Product Quality

- What to Consider for Enhanced Product Quality in Cooling Applications

- What to Expect from Industrial Cooling Systems in Quality Control

- How to Improve Product Quality with Industrial Cooling Systems

- How to Achieve Consistency in Product Quality Using Cooling Techniques

- Roundup of Top Technologies for Improving Equipment Longevity

- 7 Key Factors Influencing Equipment Longevity in Cooling Systems

- Review of Best Practices for Maximising Equipment Longevity

- Why Regular Assessments Promote Equipment Longevity in Cooling Systems

- Historical Innovations in Cooling Systems That Lengthen Equipment Lifespan

- What to Do When Cooling Systems Fail to Enhance Equipment Longevity

- How to Extend the Lifespan of Industrial Cooling Systems

- A Review of Process Cooling Technologies for Modern Factories

- Why Enhanced Equipment Longevity Is Crucial for Industrial Operations

- How to Choose the Right Cooling Systems for Equipment Longevity

- What to Consider for Improved Equipment Longevity in Cooling Systems

- Roundup of Best Practices for Enhancing Process Cooling Efficiency

- Top 10 Benefits of Effective Process Cooling in Manufacturing

- A Brief History of Process Cooling in the Manufacturing Sector

- Why Efficient Cooling Can Lead to Significant Cost Savings

- Why Process Cooling Systems are Vital for Product Quality

- What is Process Cooling and Why is it Essential for Manufacturing

- What Factors Influence the Effectiveness of Process Cooling Systems

- How to Optimise Process Cooling for Maximum Efficiency

- Roundup of Innovative Technologies in Sustainable Cooling Solutions

- How to Select the Right Cooling System for Manufacturing Needs

- Review of Best Practices for Environmentally Friendly Cooling Systems

- 7 Key Benefits of Sustainable Practices in Cooling Systems

- Historical Overview of Sustainability Trends in Industrial Cooling

- Why Choosing Eco-Friendly Refrigerants Matters in Cooling Systems

- Why Sustainable Cooling Systems Are Vital for the Environment

- What to Consider for Eco-Friendly Industrial Cooling Solutions

- What to Know About the Role of Cooling Systems in Reducing Carbon Footprint

- Roundup of Effective Strategies for Cost Reduction in Cooling Operations

- How to Assess the Environmental Impact of Cooling Systems

- How to Implement Sustainable Practices in Industrial Cooling Systems

- The Historical Evolution of Energy-Saving Strategies in Cooling

- Review of Top Energy-Efficient Cooling Systems for Industry

- Why Investing in Modern Cooling Technologies Leads to Cost Savings

- Why Energy Efficiency Matters in Industrial Cooling Solutions

- How to Evaluate Cost Reduction Opportunities in Cooling Systems

- 5 Key Benefits of Energy Savings in Industrial Cooling Systems

- What to Consider for Optimising Energy Efficiency in Cooling Processes

- What to Analyse for Reducing Operational Costs of Cooling Systems

- How to Achieve Significant Energy Savings with Industrial Cooling Systems

- Roundup of Innovations in Refrigerated System Technologies

- Review of Top Refrigerated Systems for Commercial Use

- 7 Essential Features of Modern Refrigerated Systems

- Historical Development of Refrigerated Systems in Industry

- Why Choose Refrigerated Systems over Other Cooling Methods

- How to Optimise Refrigerated Systems for Energy Efficiency

- Why Regular Maintenance is Crucial for Refrigerated Systems

- What are the Key Components of Refrigerated Systems

- What to Consider When Installing Refrigerated Systems

- How to Select the Right Refrigerated System for Your Facility

- Roundup of the latest innovations in evaporative cooling systems

- Reviewing the top evaporative cooling systems available in the market

- 7 key benefits of evaporative cooling systems for manufacturing

- Historical evolution of evaporative cooling technology

- What are the advantages of using evaporative cooling systems in industry

- Why you should consider evaporative cooling for your industrial processes

- Why are evaporative cooling systems more energy-efficient than traditional systems

- How to select the right evaporative cooling system for your facility

- What is an evaporative cooling system and how does it work

- How to optimise your evaporative cooling system performance

- Roundup of Best Practices for Implementing Water-Cooled Systems

- 7 Types of Water-Cooled Systems for Various Industrial Needs

- Review of Top Water-Cooled Systems on the Market

- The History of Water-Cooled Systems in Industrial Settings

- What are the Key Components of Water-Cooled Systems

- Why Investing in a Water-Cooled System Improves Efficiency

- Why Water-Cooled Systems Are Essential for Industrial Applications

- What to Consider When Upgrading Your Water-Cooled System

- How to Maintain Your Water-Cooled System Effectively

- How to Choose the Right Water-Cooled System for Your Industry

- Roundup of Best Practices for Air-Cooled System Maintenance

- Review of the Latest Air-Cooled System Technologies

- The Evolution of Air-Cooled Systems in Industrial Applications

- Top 5 Advantages of Using Air-Cooled Systems

- Why Air-Cooled Systems are Preferred in Warm Climates

- Why Air-Cooled Systems are a Sustainable Choice for Industry

- What to Consider When Designing Air-Cooled Systems

- What to Know About the Benefits of Air-Cooled Systems

- How to Select the Right Air-Cooled System for Your Facility

- How to Optimise Air-Cooled Systems for Maximum Efficiency

- Roundup of Recent Innovations in Chilled Water Technology

- Review of the Best Chilled Water Systems on the Market

- 7 Key Advantages of Chilled Water Systems for Industrial Use

- Historical Development of Chilled Water Cooling Technologies

- Why Chilled Water Systems are Essential for Modern Industries

- Why Energy Efficiency Matters in Chilled Water Systems

- What to Consider When Designing Chilled Water Systems

- How to Implement Chilled Water Systems in Industrial Applications

- What are Chilled Water Systems and How Do They Work

- How to Optimise Chilled Water Systems for Maximum Efficiency

FAQS

What advantages do commercial cooling systems offer compared to industrial cooling rentals for managing high power cooling needs?

Commercial cooling systems and industrial cooling rentals both provide reliable process cooling, but commercial systems are typically designed to remove heat from industrial processes and equipment more efficiently. They often incorporate advanced industrial chillers design, which takes into consideration factors like seasonal energy performance ratio (SEPR), ensuring optimal heating and cooling. When faced with real-world process temperature challenges, commercial cooling systems are often preferred for their cost-effective cooling options without capital investment. In addition, they can address logistical challenges in places like hospitals or manufacturing facilities, proving beneficial for operations like CNC machining, which needs centralised cooling to slash maintenance downtime and energy use.

How do industrial air conditioners help in overcoming real-world process temperature challenges while delivering under pressure in high-power cooling applications?

Industrial air conditioners are designed to efficiently manage high-power cooling demands by maintaining optimal temperatures even in challenging conditions. This reliability is crucial in settings where temperature control is essential for operational efficiency. Additionally, understanding the significance of the seasonal energy performance ratio (SEPR) matters for process cooling systems, as it can help businesses select units that deliver superior performance with low power consumption. By utilising advanced features like direct airflow, these cooling systems can significantly reduce power consumption while providing high capacity cooling solutions for industries faced with record-breaking heat.

How can industrial cooling systems be improved to effectively address real-world process temperature challenges while ensuring high-power cooling performance?

Industrial cooling systems are essential for overcoming real-world process temperature challenges and delivering under pressure in high-power cooling applications. Implementing a seasonal energy performance ratio (SEPR) is crucial, as it significantly impacts the efficiency of the system, especially during record-breaking heat. Innovations such as centralised cooling can provide cost-effective cooling solutions without requiring capital investment, benefiting processes like those in plastic moulding, and helping companies like Baxter futureproof their production. Additionally, proper planning is vital for upgrading critical cooling systems in facilities like hospitals, ensuring contingency cooling is reliable and efficient.

How do industrial cooling systems contribute to overcoming logistical challenges while ensuring high-power cooling performance in critical environments?

Industrial cooling systems play a crucial role in overcoming logistical challenges, particularly in environments where high-power cooling is essential, such as hospitals and data centres. These systems are designed to deliver effective temperature control while maintaining efficiency, which is vital for meeting real-world process temperature challenges, especially when delivering under pressure. By implementing advanced cooling solutions, facilities can benefit from contingency cooling options and avoid lengthy downtimes, leading to a significant reduction in power consumption and associated costs. For example, a hospital in Scotland has successfully upgraded their critical cooling systems to enhance their operational capability, demonstrating the importance of industrial cooling systems in maintaining performance standards and ensuring reliability.

How do seasonal energy performance ratios (SEPR) play a role in ensuring effective industrial cooling systems while tackling real-world process temperature challenges under high-power cooling conditions?

Seasonal energy performance ratio (SEPR) is crucial for industrial cooling systems as it measures the cooling efficiency over a season. This metric matters for process cooling because it indicates how well systems perform under varying temperature challenges and high-power cooling demands. Implementing efficient SEPR can contribute to overcoming logistical challenges when upgrading cooling systems, as seen in examples like CNC Speedwell slashing maintenance downtime with centralized cooling and hospitals in Birmingham benefiting from contingency cooling systems.

How do industrial cooling systems address the need for cost-effective cooling solutions while managing high-power cooling under real-world process temperature challenges?

Industrial cooling systems are designed to provide high-power cooling while minimizing operational costs. This is achieved through innovative technologies that significantly reduce power consumption, addressing real-world process temperature challenges effectively. Some solutions, like the centralised cooling systems from companies such as ICS Cool Energy, not only enhance cooling efficiency but also help organisations avoid capital investments, thus offering cost-effective cooling options. Additionally, implementing strategies like the flexibility of the flex hire scheme can further optimise performance in demanding scenarios, reflecting why seasonal energy performance ratios (SEPR) matter for process cooling in various applications.

How can organisations implement cost-effective cooling solutions with no capital investment to address high-power cooling needs and ensure efficiency in real-world process temperature challenges?

Organisations can benefit from strategies such as adopting free cooling systems and utilising flex hire schemes, which provide cost-effective cooling with no capital investment. This approach allows for overcoming logistical challenges, especially in critical environments, while efficiently managing high-power cooling and addressing real-world process temperature challenges by enhancing energy efficiency and reducing power consumption. Additionally, newer technologies, like centralised cooling systems, can significantly improve contingency cooling for facilities, ensuring they remain functional and efficient during extreme conditions.

How can industrial cooling systems be adapted to maintain efficiency during record-breaking heat conditions while also addressing the need for cost-effective cooling solutions?

Industrial cooling systems can be adapted to maintain efficiency during record-breaking heat by implementing contingency cooling solutions that reduce power consumption and enhance performance under pressure. Strategies such as utilising a flex-hire scheme offer organisations cost-effective cooling with no capital investment, ensuring they meet high-power cooling needs effectively. This approach helps to address real-world process temperature challenges while overcoming logistical challenges faced by facilities, such as hospitals in Scotland, that require upgraded critical cooling systems.

How do industrial cooling systems adapt to high-power cooling needs during record-breaking heat while maintaining efficiency in real-world environments?

Industrial cooling systems must adjust to high-power cooling demands during record-breaking heat by utilising advanced technology that addresses real-world process temperature challenges while delivering under pressure. For instance, systems like CNC Speedwell’s centralised cooling demonstrate how cooling efficiency can be enhanced, thereby reducing power consumption. Additionally, implementing cost-effective cooling solutions, such as free cooling schemes and flexible hire options, can significantly improve efficiency without the need for capital investment, addressing specific logistical challenges faced by industries during these high-temperature scenarios.

What strategies can be implemented to enhance industrial cooling systems while effectively tackling real-world process temperature challenges under high-power cooling needs?

To enhance industrial cooling systems while addressing high-power cooling needs, organizations can adopt strategies such as integrating seasonal energy performance ratios (SEPR) for better efficiency, utilizing portable spot coolers for flexibility, and investing in centralized cooling technologies which can dramatically reduce power consumption. Additionally, options like free cooling solutions allow for cost-effective cooling with no capital investment, particularly beneficial in industries undergoing high-power cooling scenarios. This holistic approach is essential in maintaining optimal operational efficiency during record-breaking heat conditions while overcoming logistical challenges.